In the world of manufacturing, innovation is key to staying competitive and meeting the ever-evolving demands of industries. Among the technologies driving this transformation is aluminum CNC metal spinning, a method that is redefining the production of complex metal components. This article explores how aluminum CNC metal spinning is revolutionizing manufacturing, with a special focus on its application in large format mill liners.

Understanding Aluminum CNC Metal Spinning

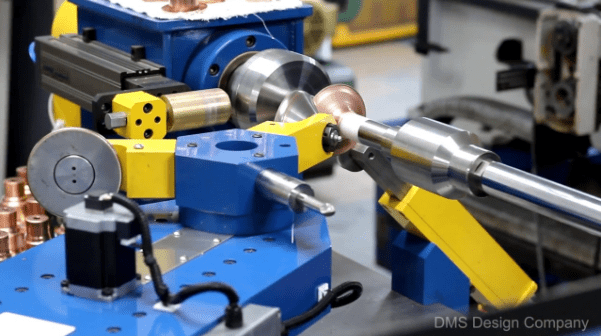

Aluminum CNC metal spinning is a precision manufacturing process that involves shaping a metal disc into a desired form using a spinning lathe. This technique, also known as spin forming, is particularly valued for its ability to produce intricate and high-quality parts with excellent surface finishes. The process begins with a flat, circular piece of aluminum being clamped onto a spinning mandrel. As the disc spins at high speeds, tools shape the aluminum against the mandrel to achieve the desired form.

One of the key advantages of aluminum CNC metal spinning is its versatility. It can produce a wide range of shapes, from simple conical forms to complex geometries. This flexibility makes it an ideal choice for manufacturing components that require both strength and aesthetic appeal.

The Impact on Manufacturing

The impact of aluminum CNC metal spinning on manufacturing is profound. Traditional methods of metal forming, such as stamping or casting, can be costly and time-consuming, especially when producing small to medium-sized batches. Aluminum CNC metal spinning offers a more efficient alternative, combining speed with precision. This method reduces material waste and allows for faster turnaround times, making it a cost-effective solution for many applications.

Moreover, the technique is particularly beneficial for producing parts with thin walls and large diameters, which are often challenging to achieve with other methods. This makes it an excellent choice for industries requiring lightweight yet durable components, such as aerospace, automotive, and industrial machinery.

Large Format Mill Liners and Aluminum CNC Metal Spinning

One notable application of aluminum CNC metal spinning is in the production of large format mill liners. These components are critical in mining and cement industries, where they protect the interior of mills from the wear and tear of grinding and processing materials. Traditionally, mill liners were made from heavy, less flexible materials, but advances in aluminum CNC metal spinning have introduced new possibilities.

Large format mill liners manufactured using aluminum CNC metal spinning offer several advantages. The lightweight nature of aluminum reduces the overall weight of the liners, which can lead to lower transportation and installation costs. Additionally, aluminum’s resistance to corrosion enhances the longevity of the liners, reducing the frequency of replacements and maintenance.

The precision of CNC metal spinning ensures that these large format liners are manufactured to exact specifications, which is crucial for their performance and fit within the mill. This accuracy minimizes the risk of malfunctions or inefficiencies during operation, contributing to a more reliable and efficient milling process.

Quality and Innovation

The quality of aluminum CNC metal spinning is a significant factor in its growing popularity. The process allows for exceptional surface finishes, which are often critical for components exposed to high levels of friction or environmental conditions. The ability to achieve smooth, precise surfaces directly impacts the performance and durability of the parts.

Innovation in CNC metal spinning technology continues to advance, with developments in machine capabilities and software enhancing the precision and efficiency of the process. Modern CNC machines are equipped with advanced controls and automation features, allowing for even greater accuracy and consistency in production.

Future Prospects

As industries continue to seek more efficient and sustainable manufacturing solutions, aluminum CNC metal spinning is poised to play an increasingly important role. Its ability to produce high-quality, complex components with reduced material waste aligns well with the goals of modern manufacturing.

The continued evolution of CNC metal spinning technology, coupled with its versatility and efficiency, suggests that this method will become even more integral to the manufacturing sector. With applications extending beyond large format mill liners to a wide range of other components, aluminum CNC metal spinning is set to revolutionize how manufacturers approach the production of metal parts.

In conclusion, aluminum CNC metal spinning is not just a manufacturing technique but a transformative force in the industry. By offering precision, versatility, and cost-effectiveness, it is changing the way complex metal components are produced. As technology advances, we can expect aluminum CNC metal spinning to drive further innovation, shaping the future of manufacturing across various sectors.