In terms of electronics manufacturing, some corporations select to companion with a number of companies: one for pcba prototypes, printed circuit board one for manufacturing, one for testing, and so on. While this may occasionally offer upfront cost financial savings, it could cost extra in the long term in the event you encounter delays in any links of the chain. That is why many firms opt for a single-company PCB assembly resolution like Telan Corporation. With regards to electronics manufacturing, some companies select to associate with a number of firms: one for prototypes, one for manufacturing, one for testing, and so forth. While this may increasingly provide upfront value financial savings, it might value extra in the long term should you encounter delays in any hyperlinks of the chain. That is why many companies go for a single-firm PCB assembly solution like Telan Corporation. One level of contact – When a number of companies are concerned within the PCB process, it is much harder to maintain everyone on the same page through the course of the mission.

Your product might find yourself handed to a special stage of manufacturing before the previous company realizes alterations should be made, and now you could have delays as the products is shipped back for modifications. Also, if the accomplished product fails, it becomes harder to pin down whom to contact for support. Solving these issues costs time and money, pushing back delivery to your prospects. With a single-company PCB service, any problem could be corrected with only one call to a single company. You don’t have to worry about miscommunication as information will get passed between a number of corporations, and you can shortly get your product back on monitor. Control Every Step of the best way – With just one level of contact, you even have extra management over the manufacturing process. You can easily collaborate along with your PCB assembly service over every side of the design. With much less hands concerned within the project, it is easier to make sure your needs and needs are being met on every degree.

Fast turnaround – For those who need a quick turnaround, your greatest selection is a single-firm PCB assembly service in New York. You eradicate the delays of knowledge relays as well as transport time between companies. With all the pieces below one roof, Telan Corporation delivers prototypes in 7-10 days and regular production in 3-4 weeks. More management over costs – A multi-company PCB process means you may be receiving several bills for the same undertaking. And since every firm is looking to make a revenue, your organization now carries the burden of their profits. By choosing a single-company PCB solution in New York, you will solely obtain one bill and one revenue margin, permitting you to complete a project for a fraction of the price. Quality assurance and worth-added engineering. As a part of our New York PCB assembly providers, we run automated optical inspections on each product. We additionally evaluate your product to search out methods you may cut back prices and/or improve its operate. We are proud to be in our fourth decade of providing excessive-high quality PCB assembly and contract electronics services in New York. From surface mount expertise to mixed technology, we have now the capabilities you are searching for. Contact us at this time and put our expertise to be just right for you.

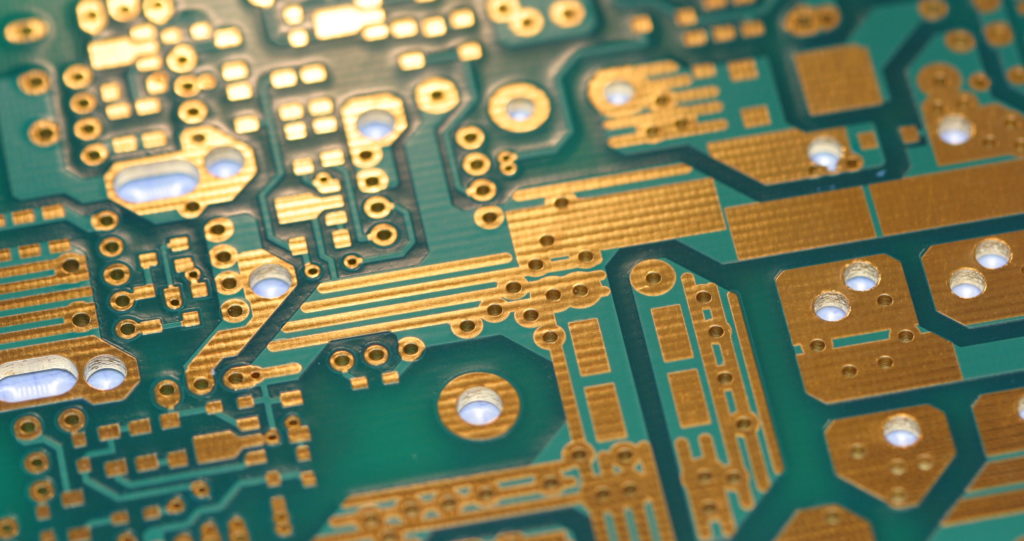

The process by which the naked printed circuit boards, PCBs utilized in electronic merchandise is evey bit as essential as the assembling with elements. PCB manufacture fundamentals How to choose the appropriate PCB producer The PCB manufacturing course of is very important for anyone concerned in the electronics industry. Printed circuit boards, PCBs, are very widely used as the idea for electronic circuits. Printed circuit boards are used to provide the mechanical basis on which the circuit may be constructed. Accordingly virtually all circuits use printed circuit boards and they’re designed and utilized in quantities of thousands and thousands. If you loved this posting and you would like to acquire more details about printed circuit board (http://www.drugoffice.gov.hk/gb/unigb/hitechcircuits.com) kindly pay a visit to the website. Although PCBs form the basis of nearly all digital circuits immediately, they are usually taken with no consideration. Nevertheless technology in this area of electronics is shifting ahead. Track sizes are decreasing, the numbers of layers in the boards is growing to accommodate for the increased connectivity required, and the design guidelines are being improved to make sure that smaller SMT gadgets will be dealt with and the soldering processes utilized in manufacturing can be accommodated.

The PCB manufacturing process may be achieved in a selection of ways and there are a variety of variants. Despite the numerous small variations, the principle levels within the PCB manufacturing course of are the identical. Printed circuit boards, PCBs, may be made from a variety of substances. The most generally utilized in a form of glass fibre based mostly board known as FR4. This gives an inexpensive diploma of stability underneath temperature variation and is does not breakdown badly, whereas not being excessively costly. Other cheaper materials can be found for the PCBs in low value industrial merchandise. For high efficiency radio frequency designs where the dielectric constant of the substrate is vital, and low levels of loss are wanted, then PTFE based mostly printed circuit boards can be used, though they are far more difficult to work with. In an effort to make a PCB with tracks for the components, copper clad board is first obtained. This consists of the substrate material, typically FR4, with copper cladding normally on each sides.

Prior to meeting of electrical components, a circuit board is named a prototype circuit board (PCB). Printed circuit board assembly, or PCB board meeting (pcba (

Prior to meeting of electrical components, a circuit board is named a prototype circuit board (PCB). Printed circuit board assembly, or PCB board meeting (pcba (

The PCB manufacturing process could be achieved in a selection of the way and there are plenty of variants. Despite the many small variations, the main levels in the PCB manufacturing process are the identical. Printed circuit boards, printed circuit board PCBs, will be made from a variety of substances. The most widely utilized in a type of glass fibre based mostly board known as FR4. This provides an inexpensive diploma of stability beneath temperature variation and is doesn’t breakdown badly, whereas not being excessively costly. Other cheaper materials can be found for the PCBs in low cost industrial merchandise. For high efficiency radio frequency designs where the dielectric constant of the substrate is vital, and low levels of loss are wanted, then PTFE primarily based printed circuit boards can be used, though they’re far harder to work with. In order to make a PCB with tracks for the components, copper clad board is first obtained. This consists of the substrate material, typically FR4, with copper cladding usually on both sides.

The PCB manufacturing process could be achieved in a selection of the way and there are plenty of variants. Despite the many small variations, the main levels in the PCB manufacturing process are the identical. Printed circuit boards, printed circuit board PCBs, will be made from a variety of substances. The most widely utilized in a type of glass fibre based mostly board known as FR4. This provides an inexpensive diploma of stability beneath temperature variation and is doesn’t breakdown badly, whereas not being excessively costly. Other cheaper materials can be found for the PCBs in low cost industrial merchandise. For high efficiency radio frequency designs where the dielectric constant of the substrate is vital, and low levels of loss are wanted, then PTFE primarily based printed circuit boards can be used, though they’re far harder to work with. In order to make a PCB with tracks for the components, copper clad board is first obtained. This consists of the substrate material, typically FR4, with copper cladding usually on both sides.