The Skyliner was gone, but there was a brand new fastened-roof Starliner hardtop coupe with sleek semifastback profile. Though less common than square-roof Galaxies, the Starliner was simply the thing for NASCAR racing by dint of its slipperier shape. Starliner bowed out after 1961, when standards had been facelifted by way of a full-width concave grille (with ’59-style insert) and a return to spherical taillights capped by discreet blades. That year’s top engine choice was the brand new 390-cid model of the FE-collection large-block. This packed 300 normal horsepower, however was obtainable, although on a very restricted foundation, as a high-compression “Interceptor” with 375 and low volume manufacturing 401 horsepower. Chunkier, more-“vital” styling marked the ‘sixty two requirements, which regrouped into Galaxie/Galaxie 500/Station Wagon traces spanning roughly the identical models. Reflecting the buckets-and-console craze then sweeping Detroit were the midseason 500 XL Victoria hardtop coupe and Sunliner convertible. The “500” stood for the 500-mile NASCAR races the division was winning (Ford won every 500 in ’63).

Bonding units with thin partitions and different delicate options will require apply. When utilizing the plasma generator, take appropriate security precautions. 1. 27. Perform quick little bends across the edges of the units. Partially-cured epoxy ought to really feel agency, rubbery, and tacky. It’s visible from underneath the machine if the edges are releasing from the PDMS. TROUBLESHOOT: If the devices aren’t clearly releasing from the mold at this stage, they’re too mushy and require more time to cure. Check back in 1 to 2 h and take a look at again. 2. 28. Holding onto the tubes, shortly pull the gadgets straight out of the PDMS. The epoxy half might deform throughout mold elimination, but it will start to relax back to its molded shape within a couple of seconds after launch. Note: Do not flip the rod. Together with your different hand, it’s also possible to strive bending the mold again away from the epoxy gadget. This helps to partially release the machine and pull the PDMS partitions away as you pull the system out.

The launched model of Wevva is significantly changed from the one mentioned within the paper, based partly on suggestions from these jams. Going ahead, certainly one of the large open questions is design of the parameterised design spaces that these apps build on. Parametric design is nicely established in areas like structure, but parameter spaces there usually fall out straight from a “universal” representation, corresponding to a NURBS floor. It seems unlikely that games have a nice common representation like this (though I’m willing to be proved unsuitable). And that is very true when the parameters are speculated to be immediately editable by end-users. Covering that is a put up for one more day, but later this summer time we will present a paper on the method we have arrived at for designing these parameter areas. Paper: Swen E. Gaudl et al. 2018). Rapid sport jams with fluidic games: A consumer research & design methodology.

But for it’s time and place it was some good execution and a few luck on timing. As Heroku sat at a central point of app deployment we actively tried to assume concerning the expertise finish to end. This manifested in among the small things we actively campaigned for and collaborated with the group members who may make these occur. A number of key examples come to mind for this. URL. Some of this originated from the 12factor concepts, others in that having 5 setting variables to define what you were connecting too felt verbose and cumbersome. URL if it have been outlined. I don’t recall the specifics here, however suspect this was one thing we nudged @hone02 to help with. The second was around some options of Postgres. On the time Postgres was going nicely, but many of the core group focused on performance or enterprise-y options. We had been coming at it from a different angle with an viewers of Rails developers. We had been intentional and engaged with among the Postgres consultancies that employed committers, rapid prototyping with a general theme of how can we assist contribute, while also advancing Postgres based on the data we’ve got from users.

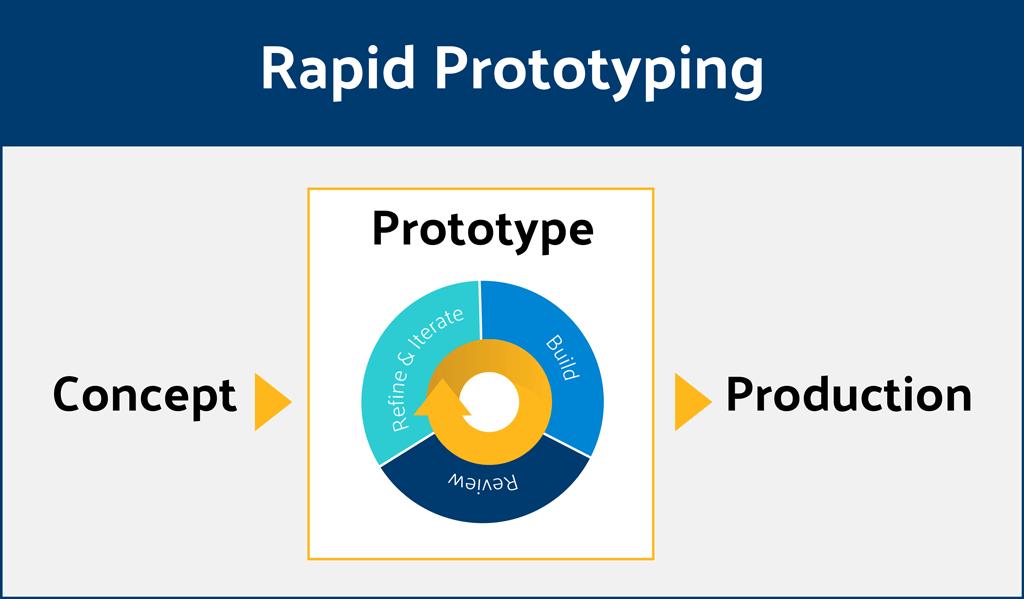

This perception impacts many design decisions the product crew will make and assist the crew create user-centered merchandise. High-fidelity prototype of a cellular app. During this stage, the workforce defines what they need to incorporate in a prototype. Every prototype must be created for a selected reason. For example, 3d printing a team might want to validate the checkout circulate, and they’re going to make a prototype with steps that customers go through once they purchase a product. There may be a big difference between creating a prototype for the whole app and creating a prototype for a particular person movement. If you beloved this article and you simply would like to collect more info concerning low volume manufacturing (https://nightcms.ru/user/nailplay0) i implore you to visit our own webpage. Having a clear objective will make prototyping more focused. A crew typically invests time in user analysis earlier than creating a prototype. They fight to know the issues that users face when interacting with a product and, based on this information, select user flows they want to prototype. For instance, the workforce can deal with a selected edge case within the checkout circulate, comparable to when a person chooses to use a specific fee technique.

This perception impacts many design decisions the product crew will make and assist the crew create user-centered merchandise. High-fidelity prototype of a cellular app. During this stage, the workforce defines what they need to incorporate in a prototype. Every prototype must be created for a selected reason. For example, 3d printing a team might want to validate the checkout circulate, and they’re going to make a prototype with steps that customers go through once they purchase a product. There may be a big difference between creating a prototype for the whole app and creating a prototype for a particular person movement. If you beloved this article and you simply would like to collect more info concerning low volume manufacturing (https://nightcms.ru/user/nailplay0) i implore you to visit our own webpage. Having a clear objective will make prototyping more focused. A crew typically invests time in user analysis earlier than creating a prototype. They fight to know the issues that users face when interacting with a product and, based on this information, select user flows they want to prototype. For instance, the workforce can deal with a selected edge case within the checkout circulate, comparable to when a person chooses to use a specific fee technique.

Making the mandatory changes and implementing them in the prototyping phase in economical and fewer time-consuming. If different methods of prototyping are used, it may be troublesome to make several modifications in the prototyping process which could, in flip, improve the cost of the production process. The ‘trial and error technique’ may prove to be costly if traditional methods of prototyping are carried out. Thus the full product development time and value are decreased and your entire process is made a lot easier due to rapid prototyping, especially if it is completed with the help of 3D printing or additive manufacturing. Rapid prototyping makes you cut down the production time drastically as in Research and improvement, initiatives needs to be completed in stipulated time .The saved time additionally reduces costs and will increase profitability. Thus, the product could be manufactured in a lesser period of time and will be made out there out there faster. In at the moment’s competitive world, bringing new and higher products to the markets before your competitor does so, determines whether or not the corporate could be profitable or not.

Making the mandatory changes and implementing them in the prototyping phase in economical and fewer time-consuming. If different methods of prototyping are used, it may be troublesome to make several modifications in the prototyping process which could, in flip, improve the cost of the production process. The ‘trial and error technique’ may prove to be costly if traditional methods of prototyping are carried out. Thus the full product development time and value are decreased and your entire process is made a lot easier due to rapid prototyping, especially if it is completed with the help of 3D printing or additive manufacturing. Rapid prototyping makes you cut down the production time drastically as in Research and improvement, initiatives needs to be completed in stipulated time .The saved time additionally reduces costs and will increase profitability. Thus, the product could be manufactured in a lesser period of time and will be made out there out there faster. In at the moment’s competitive world, bringing new and higher products to the markets before your competitor does so, determines whether or not the corporate could be profitable or not.